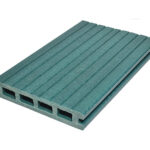

Wood-plastic composites (WPCs) are composite materials made of wood fiber or wood flour and polymers(thermoplastics). These composites belong to a great family of composites named as natural fiber/ polymer composites.

The main base polymers(thermoplastics)that applied in this type of composites are polyethylene(PE), polypropylene(PP),polyvinyl chloride(PVC), and etc.

Alvar Plast Sepahan received to the knowledge and technology of manufacturing of the WPCs by research and engineering in 2003 in ISTT(Isfahan Science and Technology Town) and then begun to manufacture machinery and technical elements for production WPCs Granules and WPCs Extruded Profiles.